Say what you will about NASA, the organisation is a serial innovator. It’s brought us more technology than most of us would ever have guessed: from camera phones, to baby formula, to LED lights, to Nike Air trainers. Continuing our series on futuristic food technologies, we next explore not Air Max but rather Air Proteins. Sounds far out, well it is a bit.

Back in the 1960s NASA was looking into ways of feeding their astronauts on long space missions where providing supplies for the entirety of the mission presented a significant, if not insurmountable challenge. By leveraging microorganisms known as Hydrogenotrophs (literally “eats hydrogen”) which have a penchant for hydrogen but also Carbon Dioxide, the great minds at NASA came up with a solution. The very same gas we exhale and that is currently causing us some amount of bother on Earth, can be fed to these microorganisms to produce nutritious protein. While you might wonder “why not simply grow vegetables on board the shuttle?” well, the remarkable efficiency of Hydrogenotrophs in transforming Carbon Dioxide into food far exceeds that of traditional plants: mere hours compared to months before harvest.

Curiously, this technology was developed solely for space travel and remained largely untouched on Earth, buried in the annals of scientific archives. However, as we grapple with the monumental impacts of animal agriculture, visionary scientists have resurfaced NASA's decades-old research, seeking to disrupt one of the most destructive industries on our planet and revolutionise the very way we feed ourselves.

A technology with enormous potential -

Finnish organisation, Solar Foods is one of these visionaries and is working to decouple protein production from our limited resources. In their own words: “Protein production is a massively disproportionate squanderer of the Earth’s resources. It’s time to enter the era of sustainable food production to liberate our planet from the burdens of agriculture.”.

Another is Air Protein. Led by Founder and CEO Lisa Dyson they plan to usher in “the Age of landless agriculture” and build “a sustainable relationship between our food and our planet.”

They’re doing this through a bioprocess which can largely be described as fermentation. Hydrogenotrophic microbes, which naturally occur in nature and our gut, are selected, placed in a bioreactor and fed the nutrients they require to multiply and proliferate into their billions. The bioprocess involves an air capture device that draws Carbon dioxide and water from the atmosphere. The water is then split into oxygen and hydrogen through electrolysis. Ammonia, serving as a nitrogen source, and essential inorganic nutrients like phosphorus and calcium — which the air lacks — are added.

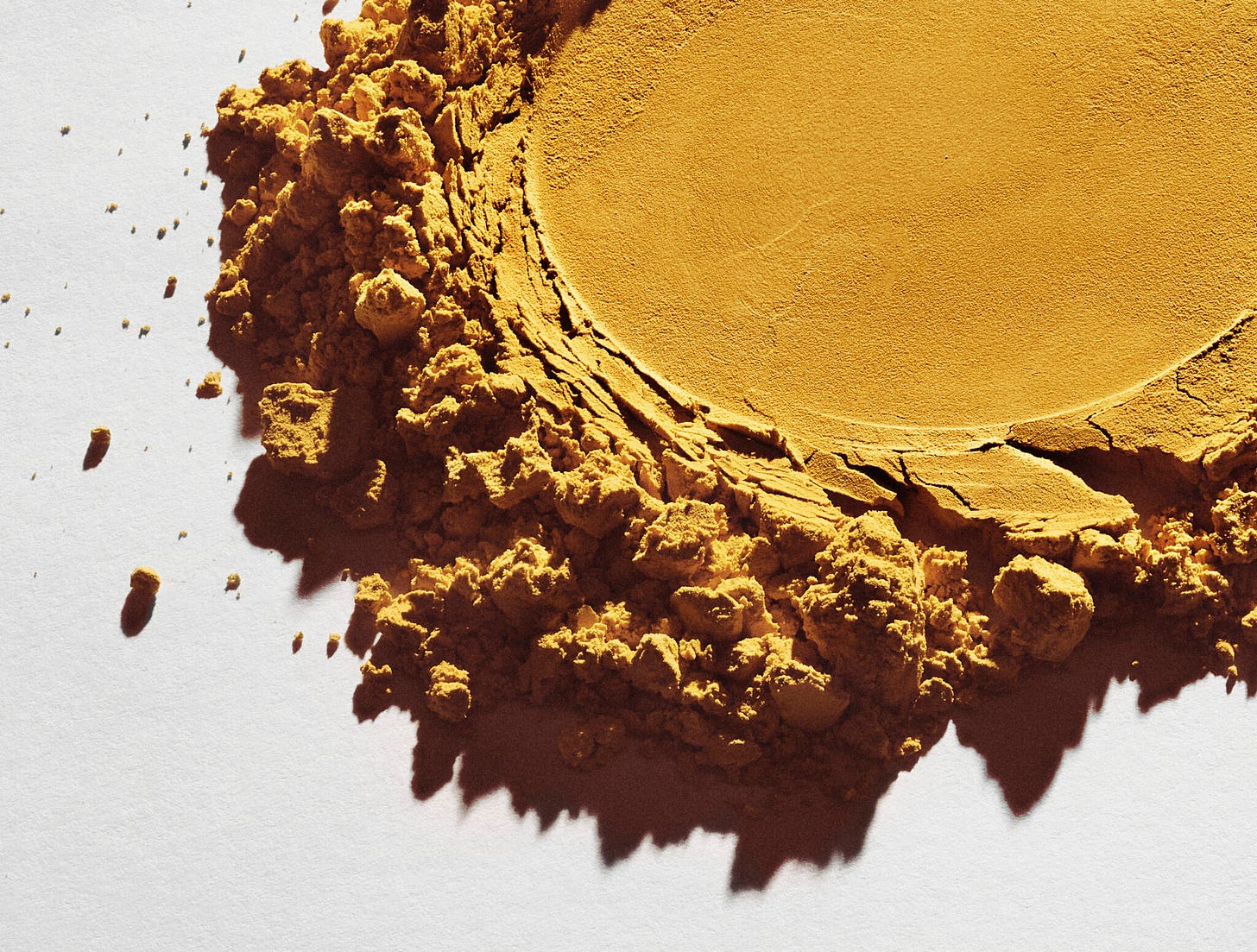

As the microorganisms proliferate, they create a thickening liquid slurry in the bioreactor. This slurry is then continuously extracted and dried to produce a powder; mainly whole microbial cells with a protein content of approximately 70%. Solar Foods calls it “Solein”. It contains all nine essential amino acids, iron, fibre and B vitamins while being completely free of GMOs, pesticides, herbicides, hormones, microplastics, heavy metals and antibiotics.

This protein powder can then be used in much the same way as flour to make bread or pasta. With traditional culinary techniques and some level of creativity we can produce a range of foods such as meats and seafood, each with differing flavours, tastes, textures, and nutritional attributes.

What’s really exciting is this technology has already been tried and tested. Air Protein created their first meat product “Air Chicken” back in 2019 and later “Air Scallop and Fish” in 2021. Solein has been successfully tested in multiple foods with different tastes and textures, ranging from alternative meat to noodles to ice cream, in fact George Monbiot tastes a Solein pancake in his book Regenesis.

According to Air Protein their technology could produce 10,000 times more food per land area than soybean crops. Calysta, another player in the field of air-based proteins, is able to produce 100,000 tonnes per year of their protein powder on 10 hectares of developed land. Producing an equivalent quantity of soy protein would require a quarter of a million hectares of arable land. The numbers for Beef and lamb are even more mind-blowing. For 100,000 tonnes we’d need 16.36 million hectares and 18.48 million hectares respectively.

Solar Foods can produce a 1kg of Solein with a fraction of the water, land and C02 needed for beef and just a few days ago made history by opening the world's first commercial scale air protein facility who’s “bioreactor can make the protein equivalent of a 300-cow dairy farm in a day without the environmental impact and demands of traditional agriculture.”

As we can see, air-based proteins require only the space for the bioreactors to sit on but they can also create an essentially unlimited food supply without the destructive side effect of our agricultural system: the animal slaughter, without the slash-and-burn of forests, without the pesticides, without the greenhouse gases, without the antibiotics and without the fertiliser run-offs.

Conclusion -

Growing our food has always depended on highly unpredictable factors: weather, geography, politics, pests, global agriculture supply chain costs, limited natural resources and manufacturing disruptions. This no longer has to be the case.

Alternative proteins and their subgroups: Cultivated Meat, Precision Fermentation, Air-based proteins, Biomass Fermentation and Molecular Farming offer us a very real climate solution and an opportunity to feed us all without destroying our planet.

But the technology faces significant hurdles. Routes to commercialisation are not always clear. For entrepreneurs, playing both the commercial game and the technological one whilst growing an industry still very much in its infancy is no small feat.

Infrastructure bottlenecks are a very real challenge. The cost to set up a commercial scale facility, known as a biofoundry, which through economies of scale will drive down costs and allow alternative proteins to reach price parity with the conventional products they are aiming to replace, is estimated at over $400 million. At a time when funding is most needed, rising interest rates, unrealistic timescales and bad publicity have scared off generalist investors. Governments should step up and lead the way to bridge the gap to price parity by shifting subsidies from Meat and Dairy to Alternative Proteins.

Consumer acceptance is another hurdle. Detractors are working hard at labelling these food products as “Frankenfood”, “Lab -grown”, “Unnatural” and so on. However, surveys have repeatedly shown that the more consumers know about the technology the more willing they are to consume its products. If Rennet, Riboflavin and Insulin are anything to go by consumers don’t appear to even be aware, let alone mind. Even so, food is deeply ingrained in culture. Education combined with outreach is essential to overcome any reservations.

The Alt Protein industry is also aggressively targeted by animal agriculture lobbies, both in the US and in Europe, see here for a comical example. Florida recently banned and criminalised the sale of cultivated meat whilst Italy instituted a sale ban in November 2023. It may well be that a technology born in Europe is blocked at home by myopic governments and incumbent industry but flourishes in Asia, leaving us behind.

Air proteins, and alternative proteins more generally, can be produced in self contained, landless and decentralised farm systems, requiring much fewer resources thus ensuring predictable costs, self sufficiency, virtually no disruptions and continuous operation in any climate.

Solar is already the cheapest form of energy on the planet. Expanding capacity will mean we can generate hyper-abundant renewable electricity at a quasi-zero marginal cost which will inevitably power all future operations. The process then becomes immensely Carbon negative since not only does it consume Carbon as a food source, it can also free up swathes of land for rewilding and reforesting. This is the real “Direct Air Capture” technology we should be talking about.

At a time when extreme climate events make food shortages alarmingly likely, when 1 billion of us go hungry, and more than 3 billion of us can’t afford a healthy diet, when deteriorating geopolitics lead to increased supply chain disruptions and food insecurity, when animal agriculture mutates the Amazon from a Carbon sink to a Carbon emitter we should be raving and embracing these technologies not hamstringing them.

If you share our vision for a sustainable food future and want to support these innovative solutions to help convince policymakers and investors, we are gathering endorsements from individuals and organisations who believe in the potential of Alternative Proteins. Send us an email at hello@webegreen.org, your voice matters in shaping a world that respects our planet's ecological boundaries.